In this first piece of the AI-Driven Reliability Engineering at Enterprise Scale Blog Series, we discuss the importance of the digital twin and C3 AI’s approach to creating digital twins in the context of C3 AI Reliability, our predictive maintenance application.

Critical Infrastructures Demand High Reliability: Nuclear Power Plant Example

With the wide adoption of technologies such as cloud computing, big data, industrial IoT, and artificial intelligence, asset-heavy industries have become increasingly interested in developing digital twins. Digital twins are software-based representations of industrial assets, and they can be used to improve safety, reliability, yield, and efficiency of operations.

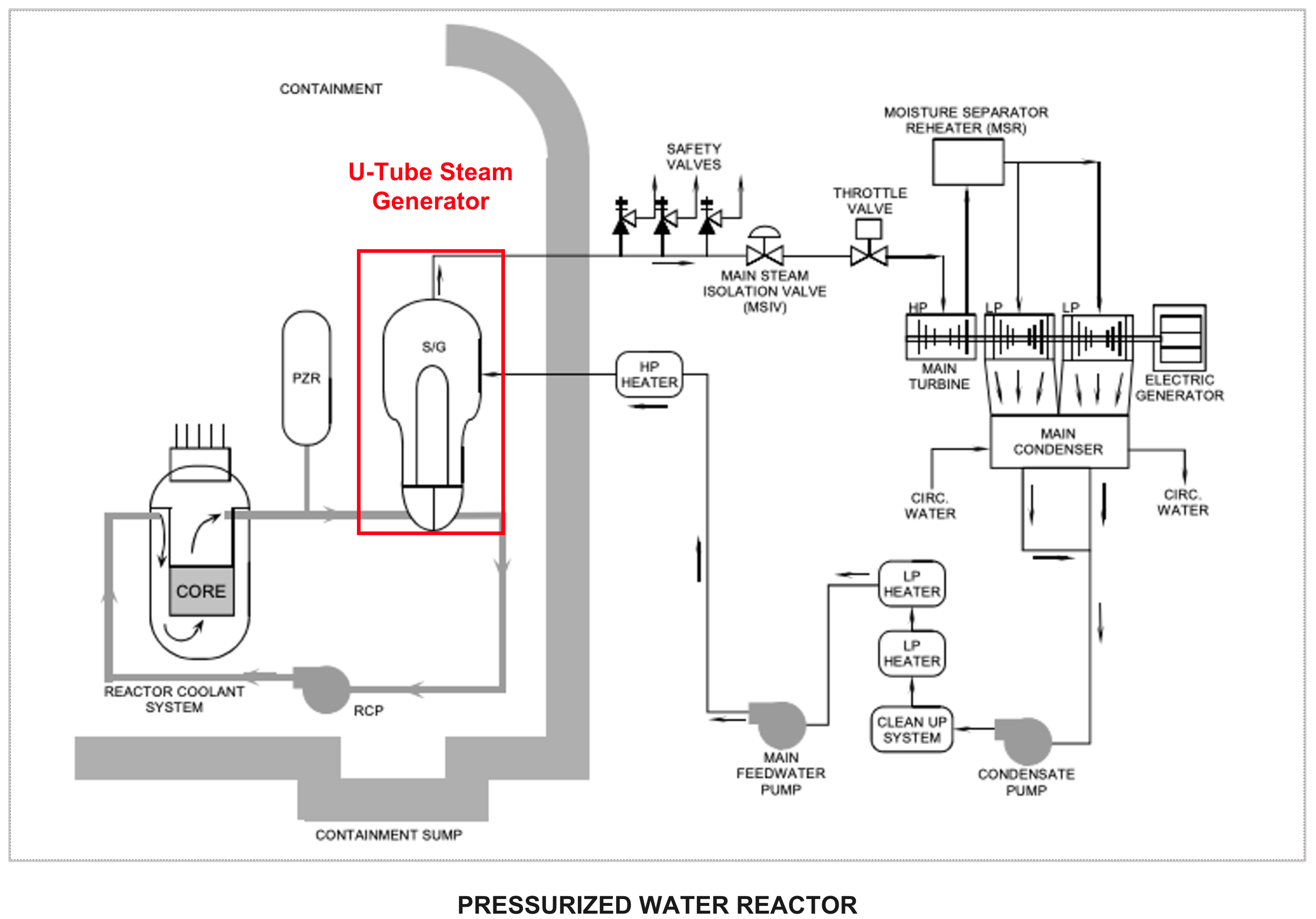

Consider a large power generation enterprise that operates pressurized water nuclear reactors across the United States (Figure 1). Each reactor uses multiple U-tube steam generators to transfer the heat between the primary and secondary coolant channels. Various forms of steam generator degradation have led to the plugging and repair of several U-tubes over the lifetime of the reactors. According to a study published in the Nuclear Engineering and Design journal, the costs associated with each repair or replacement can exceed $100 million, excluding damages and lost revenue from reduced production rates.

The energy company sees an immense opportunity to increase productivity and reduce maintenance expenses by predicting upcoming failures and degradation of steam generator tubes. Whether the company employs physics, rules, or data-driven techniques to assess the reliability of this system, the first step remains the same — creating the digital twin. In this blog we introduce how C3 AI defines digital twins and asset templates.

Figure 1. Opportunity to identify failure risks of U-tube steam generators at nuclear plants

Digital Twins are the First Step to Codifying Domain Expertise

The digital twin is a computational model of an industrial system that models the relationships between various sub-components. At C3 AI, we have seen how the digital twin is an important vehicle that allows enterprises and subject matter experts to codify their expertise about assets. The model serves as a critical foundation for advanced analytics and AI.

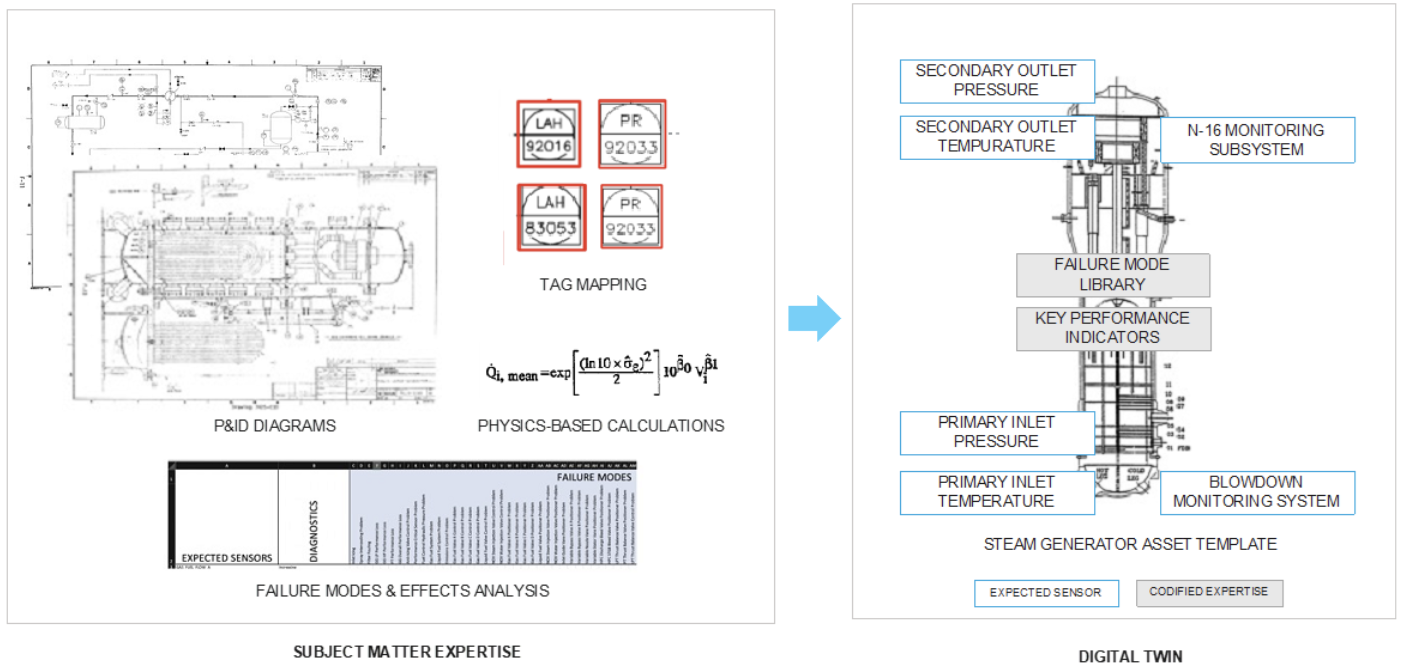

C3 AI enables digital twins in the form of asset templates. Asset templates encode contextual and subject matter expert knowledge of operating assets, including key performance indicators (KPI), sensors, tag mapping, failure modes, and physics-based calculations, to successfully employ reliability engineering techniques for a given class of assets (Figure 2).

For example, we may learn from subject matter experts that every U-tube steam generator has sensors measuring process parameters such as primary and secondary inlet pressure, temperature, and flow rate. The underlying physics of the system dictates that certain KPIs, and engineering ratios can be calculated using real-time measurements. KPIs such as shell-side and tube-side heat flux, recirculation ratio, and secondary outlet vapor density can be encoded as part of the definition of the U-tube steam generator asset template.

C3 AI asset templates also encode failure modes and recommended actions. Different types of models, whether rules, physics or AI-based, can be used to associate patterns in the real-time measurement data with corresponding failure modes. C3 AI Reliability provides several out-of-the-box model templates that detail which models work best with which class of assets based on our experience and subject matter expertise. However, as every enterprise or facility is different, we enable our users to run experiments to compare different kinds of models on historical and real-time data to embed the best models in their asset templates.

Figure 2. Codify subject matter expertise as composable asset templates

Digital twin, a computational model of an industrial system, is a critical foundation for analytics and advanced AI.

C3 AI enables digital twins using asset templates, which encode subject matter expertise about asset operations,

including KPIs, sensors, tag mapping, failure modes, physics-based calculations, and model templates.

Composable Asset Templates Enable Scalable Digital Twins

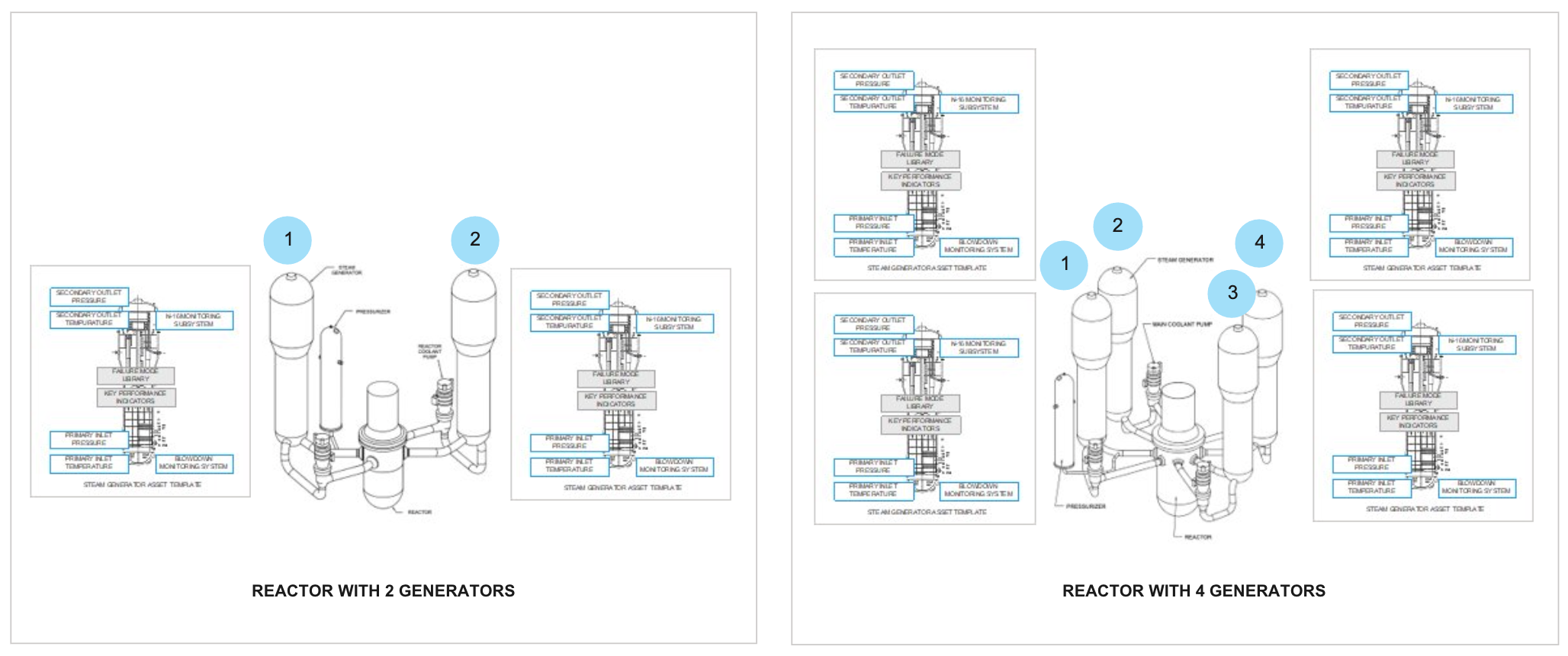

The composability of C3 AI asset templates is a critical enabler in scaling digital twins. Leveraging meta-data concepts — descriptive data about other data — and defining what data we expect to receive about an asset, we can templatize individual components of industrial assets and connect them.

By templatizing individual components, we can account for any heterogeneity between individual assets and scale out

predictive maintenance to an entire fleet of similar assets. For example, nuclear power producers may operate

similar but slightly different designs of U-tube steam generators from different manufacturers. C3 AI’s composable

asset template approach allows the operator to account for variation in instrumentation and differences at the

system level, such as the number of generators attached to each reactor (Figure 3). By taking a

composable approach, C3 AI asset templates enable a modular, scalable, and rapid digital twin

implementation.

Figure 3. Scale across identical or similar assets with composable asset templates.

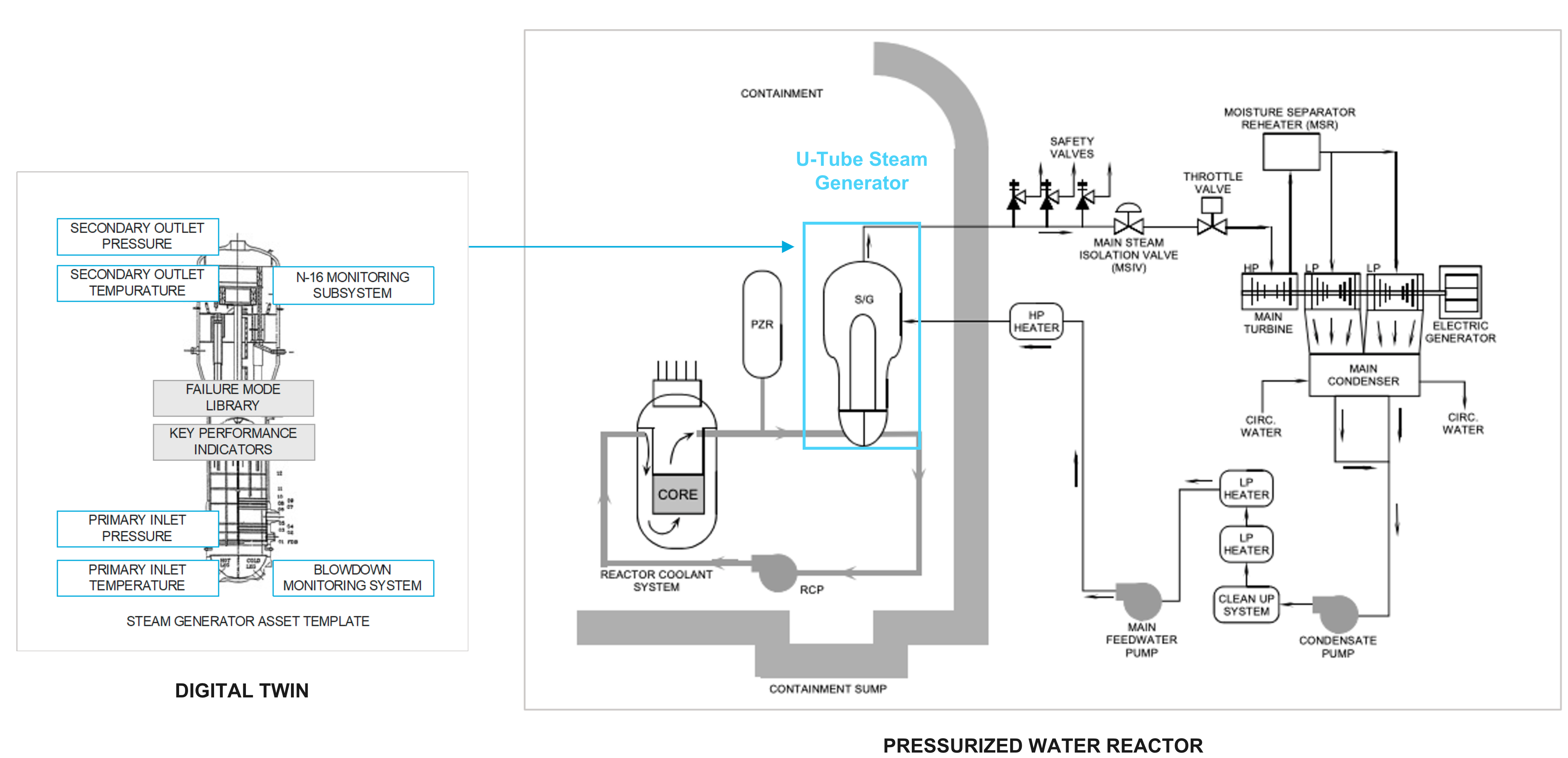

Enabling Digital Twins Across an Entire Plant

In this example, we started with the U-tube steam generator subsystem but we can use these same techniques to model the entire reactor system and scale across the entire reactor fleet (Figure 4).

C3 AI Reliability comes with a library of pre-built digital twin models for more than 30+ classes of assets such as motors, gas compressors, and gas turbines and we are constantly building more to accelerate the implementation of digital twins and AI-driven reliability engineering.

Figure 4. Model entire reactor system with scalable asset templates

Composability of C3 AI asset templates enable a modular, scalable, and rapid implementation of digital twin and AI solutions.

C3 AI enables digital twins using asset templates, which encode subject matter expertise about asset operations,

including KPIs, sensors, tag mapping, failure modes, physics-based calculations, and model templates.

Tune Back for More on AI-Driven Asset Reliability

In this blog, we explored:

- Why digital twins are an important first step in developing data-driven models

- How C3 AI applies a composable asset template approach to scale domain expertise

- The real-world example of leveraging digital twins to model safety and reliability of U-tube steam generators at nuclear power plants

In the next blog, we explore the classes of AI-driven approaches for asset reliability and what we’ve seen work best at some of the world’s largest organizations.

Up Next

Embedding AI in Reliability Engineering

About the Authors

Shrey Satpathy (author) is a Senior Data Science Instructor at C3 AI where he works with customers and customer-facing teams to implement cutting-edge machine learning applications on the C3 AI Platform. He holds a Bachelor's and Master's degree in Nuclear Engineering and has deep expertise in computational modeling of thermal hydraulic systems. He also holds a Master's degree in computer science focusing on machine learning and artificial intelligence. He is excited to be innovating at this intersection of Physics and Artificial Intelligence.

Lisa Luh (editor) is a Senior Product Marketing Manager at C3 AI, working primarily on the C3 AI Reliability Suite. Prior to C3, Lisa worked in business development for IBM’s cloud business. Lisa has an MBA from the Wharton School of the University of Pennsylvania and a B.S. from the Haas School of Business, University of California, Berkeley.